Chain hoists or electric chain hoists are commonplace lifting equipment in the maintenance industry.

Chain hoists or electric chain hoists are commonplace lifting equipment in the maintenance industry.

Maintenance is probably the most critical element of the production process.

However, it is often invisible and overlooked.

Because of this, it is not considered the star of the manufacturing process.

According to most quality gurus, production systems cannot be efficient and effective without a robust maintenance system supporting the production machineries.

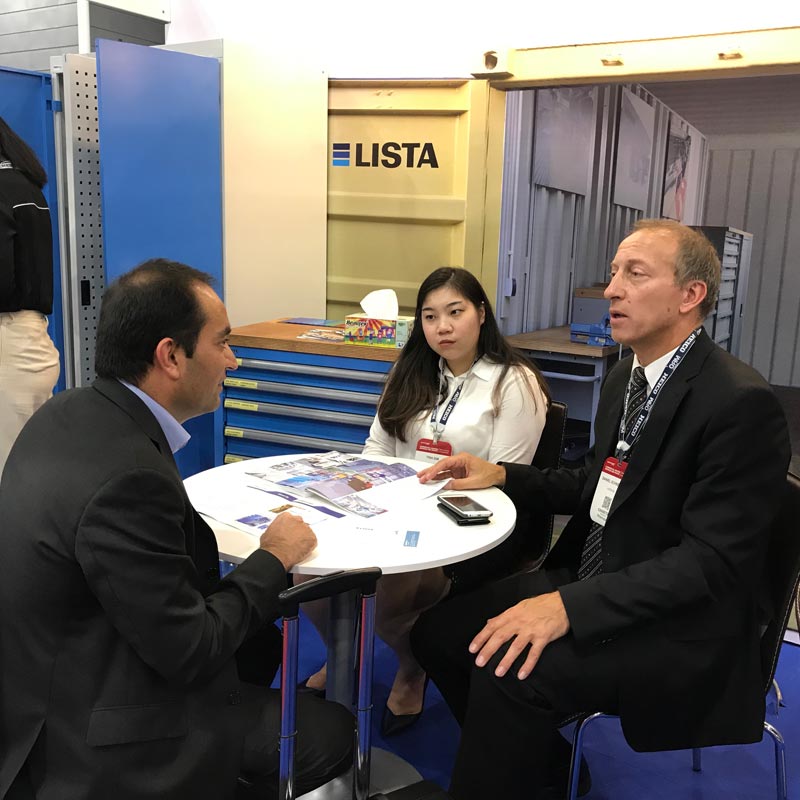

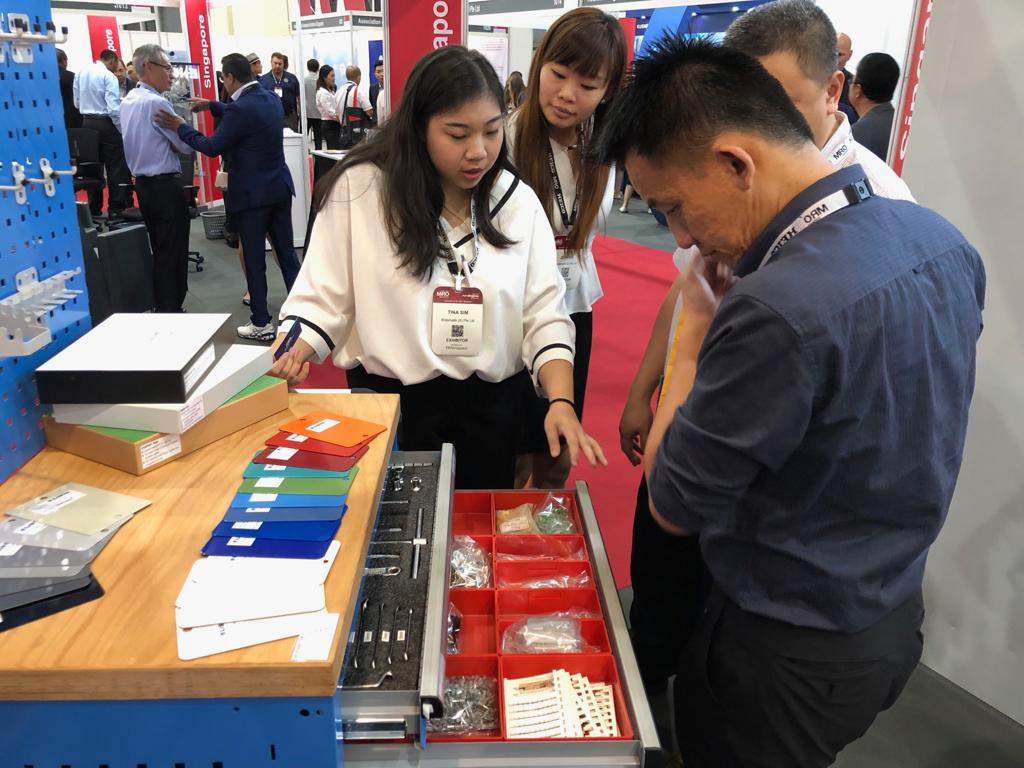

Hence, Rotomatik Singapore working closely with the customer advised that a reliable maintenance system is a pre-requisite in the overall performance of production machinery.

To cut maintenance downtime, five units of chain blocks ranging from 1 tonne to 5 tonne are setup as providing the lifting role.

All these chain blocks are installed on a monorail beam measuring 1.8 metres with a 2-metre lifting height hovering over a group of machineries.

Chain blocks are operated manually and are routinely checked to ensure they are serviceable and readily available to do the task as designed.

Another key function of a reliable maintenance system is engineering logistics.

Therefore, the customer is assured that Rotomatik Singapore stands ready to deliver servicing and parts.

KBK cranes are a flexible and configurable system that can be patterned just like a LEGO system.

KBK cranes are a flexible and configurable system that can be patterned just like a LEGO system.

It is the time of the year whereby Rotomatik celebrates her 22nd Anniversary at East Coast Park.

It is the time of the year whereby Rotomatik celebrates her 22nd Anniversary at East Coast Park.

The organizing team decided to foster camaraderie among the staff by organising laser gun shootout.

The organizing team decided to foster camaraderie among the staff by organising laser gun shootout.

A major component of electric overhead cranes is its super structure. Basically, it comprises, runways beams, columns, rails and other parts. All these come together to form a runway for the cranes.

A major component of electric overhead cranes is its super structure. Basically, it comprises, runways beams, columns, rails and other parts. All these come together to form a runway for the cranes.